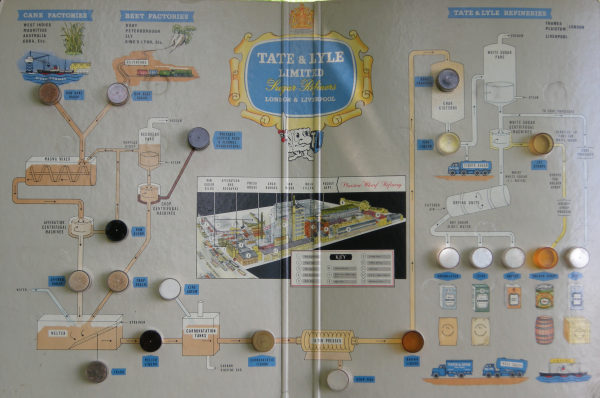

SUGAR REFINING PROCESS - c1949

|

| Tate & Lyle produced this wallchart for schools around this time. It shows the process from start to finish, including samples of each of the non-liquid process elements. Centrally is a plan of Plaistow Wharf. Purchased Ebay 2015 |

***

... and my take on another Process Chart published in 1949 ...

|

RAW SUGAR From Cane or Beet, delivered by water, road, or rail, Raw Sugar consists of impure Sucrose crystals with a film of Molasses. |

||

| |

|

|

|

AFFINATION Mixed with Raw Syrup from a previous batch to soften the adhering molasses, the resulting Magma is spun in Centrifugal Machines to wash off as much molasses as possible. |

||

| |

|

|

|

MELTING The sugar from 'affination' and 'recovery' is stirred and dissolved in hot water to the correct concentration, whilst strainers and brushes remove 'foreign objects'. |

||

| |

|

|

|

CARBONATATION The solution is treated with Milk of Lime, and Carbon Dioxide is bubbled through it causing the chalk to precipitate removing further impurities.... |

||

| |

|

|

|

FILTRATION ....which are then filtered off, the resulting Brown Liquor being sparkling bright and pale yellowish brown in colour. |

||

| |

|

|

|

CHARRING By running the brown liquor through filters of small granules of Bone Charcoal, it is decolourised and purified, leaving a water-white Fine Liquor. |

||

| |

|

|

|

VACUUM PANS The fine liquor is now drawn into the Vacuum Pans for concentration and crystalisation. It is Evaporated under reduced pressure to form Sugar Crystals. |

||

| |

|

|

|

CENTRIFUGAL MACHINES The solution of mother syrup and crystals is then spun in Centrifugal Machines leaving the White Sugar Crystals which are then washed. |

||

| |

|

|

|

GRANULATION The wet sugar is Dried in a current of hot air. |

||

| |

|

|

|

PACKAGING After grading, the Dry Granulated Sugar is packeted for the domestic market, and bagged for the commercial market. |

||

|

For further details and contemporary photographs, see : "Sugar" by JAC Hugill, Cosmos Publications, London, 1949. |

|

|

|