THE MANUFACTURE OF SUGAR

Extract from

"The Useful Arts and Manufactures of Great Britain" - London, 1846

|

As sugar is most abundantly supplied by the sugar-cane, much interest has been excited respecting the early history of this plant. It has been supposed that the Hebrew word, which frequently occurs in the Old Testament and is sometimes translated calamus, sometimes sweet-cane, means the sugar-cane. It is mentioned for the first time in Exodus, where Moses is commanded to make an ointment with myrrh, cinnamon, sweet calamus, cassia, and oil olive. The calamus does not appear to have been a native of Egypt or of Judaea; for in Jeremiah it is mentioned as coming from a far country. “To what purpose cometh there to me incense from Sheba, and the sweet-cane from a far country?” It has been argued, that if the cinnamon mentioned in the passage of Exodus were true cinnamon, it must have come from the East Indies, the only country in the world from which it is obtained; and that it is therefore, highly probable that the sugar-cane was exported from the same country. Among the ancient writers of Greece, Herodotus alludes to the “honey made by the hands of men. Nearchus, Alexander’s admiral, relates that “the reed in India yields honey without bees.” Theophrastus describes three kinds of honey; one from flowers, another from the air, (referring probably to honey-dew,) and a third from canes or reeds. Other ancient writers are more or less precise in their mention of sugar, until we arrive at the time of the Roman Emperor, Nero, when Dioscorides uses the word saccharum, or sugar: his description refers to a species of sugar-candy, but he was evidently not aware of the mode of preparing it. He says: “There is a sort of concreted honey, which is called sugar, found upon canes in India and Arabia, Felix: it is in consistence like salt, and it is brittle between the teeth, like salt.” Seneca was also ignorant of the real character of sugar: he describes it as honey found on the leaves of canes, and produced by the dew or the sweet juice of the cane itself concreting. Pliny describes sugar as brought from Arabia and India: “It is honey collected from canes, like a gum, white, and brittle between the teeth; the largest is of the size of hazel-nut; it is used in medicine only.” Galen, who wrote in the second century, also speaks of sugar; and in the seventh century, Paulus Aegineta quotes an earlier writer, who describes sugar as “the Indian salt, in colour and form like common salt, but in taste and sweetness like honey.” It appears that, during a long period, the sugar cane was confined to the islands of the Indian Archipelago, the kingdoms of Bengal, Siam &c., and that the sugar was imported with perfumes, spices and other merchandise, to the countries on this side of the Ganges. The traffic in sugar being lucrative, the Indians concealed the knowledge of the sugar-cane: they informed the merchants at Ormus that they extracted sugar from a reed, whereupon many attempts were made to obtain it from the reed-like plants of Arabia; but these were all unsuccessful. The doubts respecting the real

nature of sugar were not resolved until the year 1250, when Marco Polo visited

the country of the sugar-cane. On

his return, the merchants, who had hitherto purchased sugar at Ormus, repaired

to the country of its growth. They

brought away the sugar-cane and the silk-worm, and from Arabia Felix these

valuable productions passed into Nubia, Egypt, and Ethiopia, where sugar was

soon produced in abundance, although its quality was very inferior, from

ignorance of the means of preparing the juice.

In 1420, the Portuguese introduced the sugar-cane from Sicily to Madeira;

and, during the same century, it was probably carried from Spain to the

Canaries. So successful was the

cultivation that the sugar of these countries was preferred to any other. The Portuguese also successfully transplanted the sugar-cane to the

island of St. Thomas and other islands on the African coast. Soon after the discovery of the New World, the Spaniards established

sugar-works in Hispaniola, or St. Domingo: workmen were sent from the Canaries to manufacture the sugar, and the

cane flourished so well, that its produce afforded a large revenue to the mother

country. In 1641 the cane was transplanted from Brazil to Barbadoes,

and thence to the other West India Islands.

For a long period the use of sugar

in England was confined to medicines and feasts; and this continued until 1580,

when it was brought from Brazil to Portugal, and thence to our country.

Mr.

Porter remarks, that “The merchants who introduced the cane from India

certainly neglected to bring, also, the necessary instructions as to the methods

of preparing the juice; and the difficulties which the Arabian cultivators

experienced, doubtless caused them to try the use of all kinds of ingredients

for its purification, and to invent conical vessels for crystallizing and

cleansing the sugar.” The

Venetians introduced the art of sugar refining into Europe at the end of the 15th

century. At first they imitated the

Chinese and sold the sugar which they purified in the shape of candy, cleaning

and refining the coarse sugar of Egypt three or four times over.

They afterwards adopted the use of cones, and sold refined sugar in the

loaf. This example was soon followed by the establishment of sugar

refineries in all the commercial cities of Europe.

We

are accustomed to associate sugar only with the sugar-cane, yet it is one of the

most abundant productions of the vegetable world. It is found in a liquid state in most plants; it is

manufactured from beet-root, from the sap of the maple, and other vegetable

bodies; and this wide distribution of so valuable an article of food is one out

of the many instances of the bounty of Providence in supplying our wants.

Of the numerous varieties of

sugar, some can be made to ferment, others not; some can be formed into

crystals, others not; but it often happens that two kinds of sugar are mixed, as

in the sugar-cane, the juice of which yields the finest crystals, and also

molasses, or treacle. The size of

the crystals, however, depends greatly upon the mode of treatment: when they are rapidly formed, as in common refined sugar, the crystals

are small and confused; but when obtained by the slow evaporation of a strong

solution, they are large and transparent, as in sugar-candy.

Sugar is the principal food of the

vegetable world. It exists

largely in the succulent parts of the plants and seeds when they begin to shoot. It is formed in several kinds of seeds in the process of malting, which

consists merely in steeping seeds in water until they sprout. In the ripening of many fruits there is a similar change.

When palms are about to flower, the starch contained in their stems is

changed into sugar. If plants are

allowed to flower, the gum and sugar disappear from the roots or stems:

this change applies to such common roots as the parsnip,

carrot, beet etc, as well as to the sugar-cane maize, and other plants rich in

sugar matter. The stems of grasses

are also sweet at an early stage of their growth, when they are most nutritious

and palatable to cattle, a circumstance which ought to regulate the time for

making hay. In certain trees the

starch formed in autumn is converted into sugar by the ascending sap in spring,

and sugar is formed in considerable quantities from the sugar-maple. The sap of the birch-tree, on being fermented, yields an agreeable

beverage, called birch-wine.

The juice of grapes furnishes a

peculiar kind of sugar, called grape-sugar, which has been traced in many

fruits, such as pears, peaches, cherries, melons, dates, figs and the chestnuts

which grow in warm countries. Grape-sugar

is also formed in the nectarines of many flowers and is collected by bees; hence honey belongs to this variety of sugar.

Grape-sugar can be procured from

starch by the action of dilute sulphuric acid. Lignin, or woody fibre, or any substance containing it, can also be

converted into sugar by the same means. If

sawdust, linen-rags, paper, or other ligneous substance, be rubbed up with

sulphuric acid, and the acid

afterwards removed by adding an alkali or some powdered chalk, the ligneous body

will be changed into a species of gum, which, being boiled for some hours in a

weak acid, is gradually converted into sugar. It has been well observed that, “however clumsy and

inconvenient this process is in our laboratories, being, as we are, but

Nature’s journeyman, Nature herself carries on these transmutations with the

most wonderful results, as we see in the ripening of fruits, when the hard woody

texture gradually softens down into sweet and luscious pulp, as in the ripening

of the pear, the grape, the strawberry, and, in short, almost all fruits.”

The above varieties of sugar are

granular or crystalline, and are all capable of undergoing the venous

fermentation. The only sugar which

refuses to crystallize, but which can be fermented, is the molasses which

remains after refining cane and other sugars, and this is largely used in the

distillation of rum. Sugar of

milk and manna sugar do not ferment. The former, sometimes called Lactine, is obtained by evaporating

the whey of milk; the latter, also called Mannite, is contained in the

manna which exudes from several species of ash: it is also found in the bark of

the olive tree, in some species of pines, in the root and leaves of celery, in

the bulb of the onion, in many kinds of sea-weed, and in couch grass. By long exposure to the air the juices of many plants, such as beet,

carrot, generate manna sugar.

Sugar is extensively employed to

preserve animal and vegetable substances, such as meat, fish, fruits, jellies

and many medicinal substances; and in some cases is preferable to salt in not

destroying the true flavour of animal food. The sugar which is naturally formed in many fruits is sufficient to

preserve them, as in raisins, figs, and other dried fruits.

In temperate climates sugar is

rather a luxury than a necessary of life; but in tropical countries it is

extensively used as an article of food, and has been ranked inferior only to

corn. Enormous quantities of

sugar-canes are sent from the sugar islands to the markets of Manilla, Rio

Janeiro, and the surrounding countries. The

crude plant is called Dutrone, “the most perfect alimentary substance in

nature,” and this praise does not seem to be exaggerated when we consider its

effects upon the Negroes at the time of cane-harvest. “The time of crop is in the sugar islands,” says Mr. Edwards, “is

the season of gladness and festivity to man and beast. So palatable, salutary, and nourishing, is the juice of the

cane, that every individual of the animal creation, drinking freely of it,

derives health and vigour from it use. The

meagre and sickly among the Negroes exhibit a surprising alteration in a few

weeks after the mill is set in action. The

labouring horses, oxen, and mules, though almost constantly at work during this

season, yet, being indulged, with plenty of the green tops of this noble plant,

and some of the scummings from the boiling house, improve more than at any other

period of the year. Even the pigs

and poultry fatten on the refuse.”

In separating the sugar from the

juice some of the nutritive substances are removed; and it should not be

forgotten, that the praises bestowed on sugar by different writers on this

subject apply to the fresh juice of the cane, and not to the crystallized sugar

in use among ourselves.

The process by which raw or brown

sugar is converted into white sugar are of a striking and interesting character. Of late years they have been subject to considerable improvement, and

they now partake largely of the scientific character of our most important

manufactures.

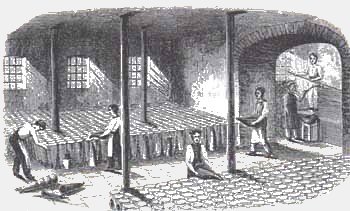

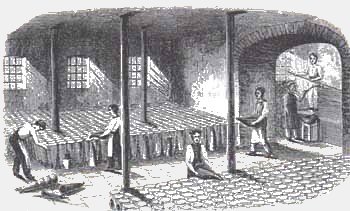

The principle sugar refineries in

London are situated in Whitechapel and its neighbourhood: most of them are extensive buildings, each consisting of seven or eight

stories; the rooms, or working-floors, as they are called, present a

singular appearance. Each floor is paved with stone, is of small height, and the

ceiling is formed of brick arches, supported on iron pillars; the object being

to render the building fire-proof and of great strength, and also to provide an

extensive surface for arranging the sugar in the different stages of the

process. A square opening is left

at the side of each floor, over which, in the top floor, is a crane, for the

purpose of removing the sugar as occasion requires.

The reader may perhaps be able to

form a tolerably accurate idea of the art of sugar refining, from the following

attempt to trace the sugar from its raw to its refined state. The description applies to an extensive refinery at Whitechapel (Messrs

Fairrie’s), which, in company with an artist, the writer was privileged to

visit.

Sugar from the West Indies is

packed in hogsheads, and that from the East Indies in canvas bags, covered with

matting. These are received into

the first floor of the refinery, situate in a little above the street, where

they are broken open and unpacked by the side of a large circular vat or

cistern, which is pouring forth clouds of steam, and filling the floor with an

oppressive sickly vapour. In this

cistern, the sugar is first mixed with water, with the addition of a small

quantity of lime water and bone black. Heat

is applied by means of steam, which issues from a number of small copper pipes,

contained at the bottom of the vessel, and from this method of applying heat the

vessel is called the blow-up cistern, the steam forcing itself by its own

pressure, or blowing up, through the mixture.

The perfect solution of the sugar is promoted by stirring with long

poles. Shortly before the liquid

has attained the boiling point it is allowed to flow along a channel into a

filtering apparatus, situated in the room beneath; on leaving which it appears

as a clear reddish syrup.

The chief object of this process is

to separate mechanical impurities, such as dust, dirt etc. from the sugar. Until within a few years the process was conducted in a ruder and far

less direct manner. The raw sugar,

mixed with lime-water, was heated in a large open copper by a fire from below,

and when warm a considerable quantity of bullocks’ blood, technically called spice,

was stirred in. The serum or watery

part of the blood, (consisting chiefly of albumen, of which white of egg is a

familiar example) becoming curdled by the heat, and entangled most of the

impurities floating in the solution raised them to the surface in the form of a

thick scum, which was carefully removed. This

process was sometimes repeated two or three times, with fresh quantities of

blood, and from the scummings a low quality of sugar was afterwards obtained. The liquor being thus clarified, was filtered through a thick woollen

cloth, and afterwards boiled in an open copper until sufficiently concentrated

for graining. So imperfect was this

method, that, in order to produce loaves of the finest quality, a second

refining was necessary; the loaves first produced were broken up and

re-dissolved, and clarified with white of egg; this being carefully skimmed off,

a small portion of indigo was added, the effect of which was to neutralize the

yellow colour of the syrup. These

costly methods, which of course greatly increased the price of sugar, are now

rendered unnecessary; for, in the modern process, a clear liquor is obtained

without the aid of so offensive a substance as bullocks’ blood, a portion of

which generally become entangled with the sugar, and was not separated by

crystallization.

The filtering apparatus now in use,

is arranged in an ingenious manner. It

consists of square vessels of iron, about eight feet high, connected with

cisterns above and below, and containing a number of twilled cotton cloth tubes,

closed at the lower ends, but open at the upper ends, which are screwed into the

floor of the upper cistern. Within

each tube is a bag of cotton cloth, which, being considerably wider than the

tube, hangs down in folds. About

sixty tubes, thus arranged, are contained in each filter, so that by this means

an extensive filtering surface is obtained; the liquor from above, having to

pass through the meshes of the cloths, is strained of most of its solid

impurities, and a clear reddish syrup drops into the cistern below. The bags soon become clogged up, and are frequently removed for the

purpose of being cleansed. A black

viscid mud is scraped off, but, as this contains a portion of saccharine matter,

it is again boiled and otherwise treated before it is transferred to the dealers

in manure.

It is obvious that, in order to

produce white sugar, the syrup or liquor must be without colour. When it leaves the filters it is of a dark red colour, and to remove this

is the object of the next process, the introduction of which is one of the great

modern improvements in the art of sugar refining.

Chemists have discovered the

existence of a remarkable attraction between animal charcoal and the colouring

matters furnished by animal or vegetable substances. This kind of charcoal (or as it is sometimes called, bone-black,

or bone-charcoal) is produced by heating bones to redness in a close

vessel, or when covered over the sand. The

bones lose about half their weight by being calcined; they are then pounded in a

mill into a coarse granular state like gunpowder, in which they are fit for use.

The charcoal filter at Messrs

Fairrie’s are oblong vessels, about five feet in height furnished with a

double bottom, the upper one being pierced with holes and covered with cloth to

prevent the holes being choked up and the particles of charcoal being carried

away by the liquor. The charcoal is

heaped up on this cloth to the depth of three feet, and the reddish liquor from

the cistern above is allowed to flow in a gentle stream over the surface; it

slowly sinks through the mass, gradually losing its colour, until it arrives at

the space below, when it is colourless. A

series of pipes and siphon tubes from the various “charcoal cisterns” as

they are called, conveys the filtered liquor into reservoirs, whence it is

pumped up to the sugar boilers in the room above.

In the course of a few days the

charcoal becomes foul and unfit for use. Water

is passed through it to remove all saccharine matter, and it is then taken to

the retort-house and re-calcined, a process which restores all its valuable

properties.

The next process which the liquor

undergoes, namely, the boiling preparatory to crystallizing, is one of the most

important in the whole range of operations to which the sugar is subjected. By the old method the syrup was concentrated in the open pans, standing

over fires, and heated to 240° or 250° Fahr. This high degree of heat was very injurious to the sugar, for it changed

a large portion of it into treacle, which had to be got rid of in the moulds. The method was also objectionable on account of its danger, and the

difficulty of managing the heat. Many

plans were adopted for heating the liquor, by passing steam pipes through it, or

hot oil under it, but they were all superseded by the valuable invention of the

Honourable Edward Charles Howard, now in general use under the name of

Howard’s vacuum-pan, first introduced in 1813. The principle of this invention rests on the fact, that the boiling

points of all fluids are considerably lowered by placing them in vacuo. Thus, under ordinary circumstances, water boils at 212°, the pressure of

the air, which is equal to about fifteen pounds on every square inch of surface,

preventing the rapid formation of vapour at a lower temperature; but if water,

at the temperature of 90° or 100°, be placed under the receiver of an

air-pump, and the air be exhausted, the water will boil rapidly and pass off in

vapour. The object, therefore,

which the inventor of the new method had to view was to collect a sufficient

quantity of syrup in a closed vessel placed in connextion with an air-pump; then

to remove the air, and apply a very moderate degree of heat, by which means the

syrup could be boiled at a low temperature, and brought down to the granulating

pitch. After numerous trials and

failures the inventor was rewarded with success, and continued during several

years to derive a large income from premiums paid by sugar refiners for

permission to use the patent process. The

patent having now expired, no restriction is placed upon its general use.

The vacuum-pan consists of a large

copper vessel, about six feet in diameter, supported on legs, so that every part

may be conveniently inspected. The

lower part of the pan is double, for the purpose of letting in the steam which

is used to heat the syrup: within

the pan, in contact with the syrup, is a coil of copper pipe, through which also

steam is passed. The bottom cavity,

or steam-jacket as it is called, is supplied with low pressure steam, but

the spiral pipe is filled with high pressure steam, which is considerably hotter

than boiling water, and greatly promotes the evaporation of the syrup. From the centre of the dome rises a neck, which, by means of a bent tube

and other apparatus, connects the interior of the pan with the air-pump used for

extracting the air and vapour. The

interior of the pan is also connected by means of pipes with vessels containing

the clarified syrup which may by situated in the upper stories, or in the

charcoal-filtering room below. In

the former case, the syrup runs down into the pan on turning a stop-cock in the

pipe, and in the latter case it rises by atmospheric pressure, as soon as a

partial vacuum is formed in the pan. The

pan is furnished with a barometer or manometer, for showing the state of vacuum,

and also with a thermometer, for indicating temperature. There is also a cistern-pipe for receiving any syrup which may

accidentally boil over; but the too rapid boiling, and also the danger arising

from the pressure of the air on the outside, which might crush in the pan, are

prevented by a safety valve, which admits air in case the exhaustion should at

any time be made too perfect. There

are numerous other minor details, which need not be particularised.

The pans generally contain each

about 100 gallons of syrup, which yield about eleven cwt of granulated sugar at

every charge. Sometimes the pans

are of larger dimensions. Dr. Ure

mentions one in use at a London house, which works off eighteen tons of

sugar-loaves daily.

The pans being properly charged,

and steam admitting within the steam-jacket and the coiled pipe, and the

air-pump is set in action, its moving power being supplied by the steam-engine

of the establishment; the syrup

soon attains a temperature of about 130°, when it boils, and throws off vapour

of water, which is pumped off, and condensed in a vessel placed in the open air,

over which a steam of cold water is constantly flowing. As the syrup becomes more concentrated,

its boiling point becomes higher: the temperature is, therefore, gradually raised to about 150°, which is

about 100° lower than would be required for open vessels. The attendant is enabled to watch the process by means of a very

ingenious contrivance, called a proof-stick. This consists of a cylindrical rod, exactly fitting a hollow tube which

enters the pan in a direction slanting downwards. The upper end of the rod is open; the lower end, which dips into the

syrup, has a slit on one side of it, about half an inch wide. Within this tube is another shorter tube, which can be moved round in it

through half a circle: near the lower end of this tube is a lower hollow which

corresponds with the slit in the outer tube; and the upper end is connected with

a handle. By making the slit and

the cavity coincide, the latter is filled with sugar; then, by turning the stick

round through half a circle, the slit is covered by the fixed tube, and the

inner tube can then be drawn without allowing air to enter the pan.

The sugar is tried by the touch, as

already explained: the small crystals which appear in it are examined, and the

moment the liquor has attained the granulating pitch, the connection of the pan

with the air pump is cut off, air is admitted to equalise the pressure, and a

plug at the bottom of the pan is opened, by means of a lever attached to it,

when the whole of the syrup flows down a pipe into a receiver situated in the

room below.

In our notice of the process of

sugar-boiling in the West Indies, it was stated that, as soon as the syrup was

boiled down to the point of granulation, it was transferred to a vessel called a

cooler, the process of boiling in open vessels raising the liquor to so

high a temperature, that cooling is absolutely necessary to crystallization. The introduction of vacuum pan has wrought a curious change; for, after

the boiling is complete, the syrup is removed, not to a cooler, but to a heater,

where it is raised to the temperature of 180° or 190°, the object being to

make the syrup more fluid than the comparatively low temperature of the pan

admits of, and also to prevent crystallization before the sugar is poured into

the moulds; for, were this to take place, the colouring matter would be so

imbedded in the mass of crystals, that no after treatment, short of re-melting,

would get rid of it. Not only,

therefore, is the temperature of the syrup raised, but men are employed with

poles in beating and stirring it up, where it is being removed to the moulds.

The heater is a shallow vessel of

copper, surrounded with an iron steam-jacket for keeping up proper degree of

heat. The syrup which flow into it

from the pan is no longer a limpid, colourless fluid, as it was in the

filter-cisterns; it is now exceedingly thick and viscid, and the process of

boiling has concentrated the colouring matter, the molasses, and

uncrystallizable parts of the sugar, to get rid of which is one of the objects

of the concluding processes.

The sugar is next removed to moulds

in the fill-house, which is situated in the lowest story, and on a level

with the heater. The conical sugar

moulds are made of brown earthenware, or of sheet iron well covered with paint;

the pointed ends are open; and the moulds vary in size according to the quality

of the sugar, the largest moulds being used for the inferior sorts. At the time of the writer’s visit to the fill-house, one set of men

were engaged washing the moulds, and putting them up in piles to drain. A second set rolled these piles to another part of the floor, and placed

them one by one, with their points upwards; a third set were occupied in

twisting pieces of paper, with which they plugged up the holes in the moulds; a

fourth set were setting up the moulds, points downwards, an operation simple in

appearance, but requiring a level floor, and that kind of ready skill which can

only be attained by long practice. Beginning

at one corner, the moulds were arranged in ranks, four or five deep, along the

whole length of the floor. A fifth

set of men, eight or ten in number were engaged in filling the moulds; each man

was naked from the waist upwards, and was furnished with a copper basin, which

he filled at the heater by opening a kind of sluice at the side, and then with a

rapid step conveyed the syrup to the moulds, and poured it into them. Each man carried enough

to fill one mould, and about half of another. A sixth set of men immediately stirred round the sugar in the moulds, to

diffuse the crystals equally through the viscid mass. In this way the filling proceeded until the contents of the heater were

exhausted, and as the moulds were filled, fresh rows were arranged in front of

the former; until at length a considerable portion of the extensive floor was

occupied. Part of this busy scene

is represented in the frontispiece.

Matters remain in this condition

until the next day, when the sugar has become partially solid: the moulds are then moved through the pull-up hole into an upper

floor, which is maintained, by means of steam-pipes, at a temperature of 80°;

the paper plus are removed, and a wire is passed through the hole to ensure an

open channel; the moulds are then set in earthen jars, or are hung in a frame

work over a gutter terminating in a

sunken cistern. The syrup which

flows off is of a greenish colour, and being collected and reboiled with raw

sugar, it produces an inferior quality of lump sugar; this again furnishes a

syrup, which supplies a yet lower description of sugar, and when all the

crystalline particles have been removed, the residue is sold as treacle.

In the course of two or three days

the drainage is complete: but there

still remains a portion of syrup and uncrystalline matter entangled with the

solid sugar. To get rid of this, a

process of washing is adopted, which, under the old method, was performed by claying,

as

already described; but now by a process, one of Mr. Howard’s valuable

improvements, which accomplishes the work in one-fourth of the time formerly

required. Some finely clarified

syrup is made by dissolving warm water loaf sugar, consisting of the turnings

obtained by a subsequent process and such loaves as do not satisfy the critical

eye of the refiner, either by their shape or crystalline texture. The syrup thus obtained is poured to the depth of about an inch, upon the

broad part of each cone, the surface of which has been previously broken up and

made level by an iron tool called a bottoming trowel. As

this syrup is concentrated, it can dissolve none of the sugar already

crystallized but readily unites with molasses and colouring matter which do not

crystallize, and gradually drains away with them. The loaf improves in whiteness, from the base to the point, every time

this operation is performed. A few

moulds are emptied from time to time to examine the success of the blanching;

and when the loaves have acquired as much colour (as the whiteness is called by

the refiners) as is judged necessary, and are sufficiently dry, they are netted,

that is made net, or neat, in appearance.

The

moulds are taken one by one, and placed across a trough, and the base scraped

with the bottoming-trowel, so as to produce an even surface: this operation is

called brushing-off. A few blows being applied to the mould, the sugar is loosened, and turned

out upon its base. If the sugar is of the best quality, it is of a perfectly

pure white, from the base to within five or six inches of the point, and here a

portion of moisture and colouring matter still remains, which is removed by the

process of turning off. This is

effected by cutting blades, arranged in a conical form, connected with

wheel-work, to which motion is given by one man, while another gradually

introduces the loaf within the space formed by the knives, whereby the coloured

damp portion is removed, and the loaf improved in shape. Loaves of coarser sugar are not turned off, but the damp ends are cut

off, leaving them in the form of a truncated cone. The loaves are then removed to an oven, which occupies nearly

the whole height of the building, upon a base of not more than ten feet square. This oven is provided with open frames,

from the base to the top, upon

which the loaves are arranged, and a constant temperature of about 140° is

maintained, by a numerous assemblage of steam pipes. When sufficiently dry, the loaves are taken out, tied up in paper, and

are then fit for the grocer’s shop.

The routine of operations at the

refinery takes about a fortnight, during which various qualities of sugar are

produced; first, white loaves of the finest quality, obtained directly from the

raw or muscovado sugar; secondly, a second quality called lumps, composed of the

second runnings, which are the syrup used in washing the loaves after the green

syrup is separated; thirdly an inferior quality, composed of the green syrup,

mixed with the raw sugar, producing what are called bastards. These are crushed into powder, and sold as a superior kind of moist

sugar; fourthly, several inferior kinds of sugar are produced from the refuse

matter, consisting of the impurities collected in the bag-filters, the scrapings

of the various floors and the waste, which in the several departments of an

extensive refinery is necessarily great. All

these sources of sugar are carefully collected; the crystalline particles

separated from the treacle, and this again from dirt, and other impurities,

which are finally sold as manure. Every

third week the routine is again commenced, and carried on during another

fortnight of twelve days; for it is satisfactory to learn that, in this

manufacture, Sunday is a day of rest.

As some of the different qualifies

of sugar are being forwarded a stage at the same point of time, the stranger is

somewhat embarrassed to notice such various results produced, as it were, by the

same means. But on clearly

understanding the economy of the refinery, he will be able to trace the pure

white loaves, from the raw sugar in the hogshead to its final completion,

passing over, as accidental or subsidiary, the various arrangements whereby

inferior loaves are produced, or in other words, whereby waste is prevented. In such a case

the refinery presents points of the highest interest. It is curious to witness the application

of so much science, ingenuity,

skill, and capital; to the production of an article which, after all, is one of

mere luxury, and according to Dr. Prout, is inferior in nutritive properties to

the raw sugar which furnishes it, a circumstance which may afford some

satisfaction to those persons whose means will not allow them to use white

sugar. The working floors of the

refinery, containing many thousand moulds filled with sugar, are peculiarly

striking. The utmost care is taken

to guard the sugar from speck or stain, but the floors themselves are not so

privileged: during the processes of

filling and washing, small quantities of syrup are being constantly spilt, and

this is soon trampled into a thick viscid mud, which adheres to the feet, and in

some places actually impedes motion. Heat

is every where present, and often to an oppressive degree, but its source is

seldom seen; the system of heating by steam has enabled the refiner to regulate

the supply of heat as he may desire, and has also rendered perfectly safe a

process which was formerly very hazardous. The effect of the various modern improvements has greatly reduced the

price of refined sugar; at one time its price was 40 per cent greater than raw

sugar, but now the difference in price is not more than 20 per cent.

The consumption of sugar

in different years is liable to great fluctuation, arising from variation in

price, and the means of the people to purchase; but it has been calculated that

the annual consumption averages about 20 lbs per head for Great Britain; about 5

lbs per head for France; 4lbs for Germany; and about 2½ lbs for other parts of

Europe.

In the year 1839, the

quantity of cane sugar produced in different parts of the world was estimated as

follows:

Cwts

The British Sugar Colonies

Exported

3,571,378

British India

Exported

519,126

Danish West Indies

Exported

450,000

Dutch West Indies

Exported

260,000

French Sugar Colonies

Exported

2,160,000

United States of America

Exported

900,000

Brazil

Exported

2,400,000

Spanish West Indies

Exported

4,481,342

Java

Exported

892,475

Exported for internal consumption, exclusive of China,

India, Siam, Java and the United States

2,446,337

18,080,718

Between one-fourth and one-fifth of this quantity is consumed

in the United Kingdom. The

quantities imported during three years are as follows:

1839

Cwts

1840

Cwts

1841

Cwts

West India, of British Possessions

2,823,931

2,202,833

2,145,500

East India, of British Possessions

518,925

482,824

1,239,738

East India, of Foreign Possessions

722,777

-

803,668

Mauritius

612,009

545,009

716,112

Foreign

722,777

805,179

-

The duty of sugar from British possessions was during many

years 24s per cwt; foreign sugars paid a duty of 63s per cwt. The net revenue from this source, for 1839 was 4,586,936l.; for 1840,

4,449,033l; and for 1841 5,114,390l. By

a recent act of the legislature the duties payable on the importation of sugar,

subject to minor exceptions, depending on reciprocity treaties, and other

circumstances, are as follows:

Sugar grown in British West Indies or East India

Per Cwt

Double Refined

£1.

1. 0

Refined

0.18.8

Clayed

0.16.4

Brown or Muscovado

0.14.0

Molasses

0.5.3

Sugar grown in other British Colonies

Clayed

1.1.9

Brown

0.18.8

Sugar grown by free labour in Foreign Countries

Clayed

1.8.0

Brown

1.3.4

Sugar grown by slave labour in Foreign Countries

Refined

8.8.0

Brown

3.3.0

Molasses

1.3.9

Before these alterations, refined sugar was not allowed to be

made in any of our colonies, but was reserved for the advantage of this country: considerable

quantities were, therefore, annually exported. In the year ending 25th June 1840,

the chief export of British

refined sugar was as follows:

Cwts

To Italy

40,000

To British North America

37,000

To Turkey

30,000

To Russia

20,000

To Australian Settlements

11,000

To British West Indies

10,500

Although foreign sugar paid nearly three times the duty

charged on our colonial sugar, yet the refiner was permitted to refine it in

bond for exportation, a drawback being allowed in the proportion of 34 cwt. of

raw to 20 cwt. of refined.

The men engaged in the sugar refinery appear to enjoy average

good health. In some of the

processes, they are exposed to a warm damp atmosphere and in others to hot dry

air; but they are not long enough at them to suffer injuriously, the nature of

the work leading them to conduct other processes which are rather healthy than

otherwise. The preparation of the

bone black is peculiarly disagreeable and dirty, the air of the room in which it

is performed being very hot, and loaded with particles of dust; but this is

usually a separate trade.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|